ATC Drivetrain, an independent remanufacturer of automotive powertrain and drivetrain systems in Farmington Hills, has launched remanufacturing capabilities for electrified vehicle systems at its Oklahoma City facility to serve the North American market.

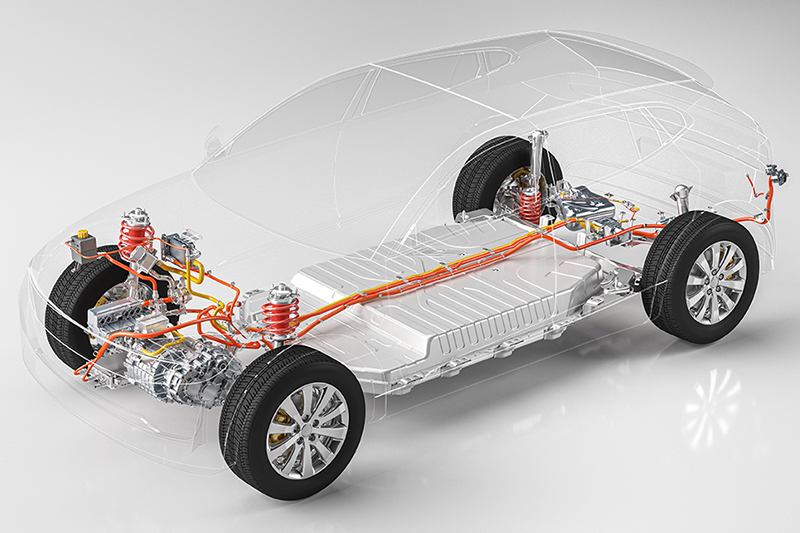

The investment allows ATC to remanufacture batteries and electric drive units for hybrid and battery electric vehicles. The move represents the next step in the company’s electrification strategy and builds on the competencies and processes initially developed in the United Kingdom.

ATC currently remanufactures batteries and drivetrains for electric vehicles at its facility in Cannock, England.

“As the industry continues the migration towards electrification, it is strategically important for ATC to build out the necessary capabilities and capacities to globally support our customers for all of their powertrain and drivetrain remanufacturing needs, regardless of propulsion technology,” says Greg Heald, president and CEO of ATC.

Al Victoria, vice president of engineering and quality at ATC, says: “With our existing capability in the U.K., the launch of these competencies in the U.S. and the upcoming launch in China, we expect to be the first and only independent remanufacturer with global capacities for ICE, hybrid and fully-electric vehicle solutions.”

According to ATC, the process of remanufacturing recaptures the original value of the product. Approximately 85 percent of the energy expended in the manufacturing of the original product is preserved in the remanufactured version.

ATC specializes in the remanufacturing process that requires:

- Complete disassembly of a transmission or engine and subsequent salvage of suitable components.

- Reassembly of transmissions and engines with a combination of new and recovered components.

“Since our initial investment in ATC in 2018, the company’s strategy has been to make targeted investments around the world to prepare for an increasingly electric future,” says Alex Rose, chairman of ATC Drivetrain and co-president and partner of Crestview Partners.

“The launching of ATC’s new North American EV lab is one more exciting step on the company’s journey towards global leadership in providing environmentally friendly remanufacturing solutions to our customers.”