Rochester-based FANUC America, a leading provider of robotics and CNCs, and the Manufacturing Skill Standards Council (MSSC), the leading U.S. council for certifying technicians with the foundational skills needed for careers in logistics and advanced manufacturing, have recently partnered to combat a lack of robot operators and technicians in the workforce.

Through the alignment of similar businesses, they will co-market their respective industry certifications.

“The collaboration between FANUC and MSSC will provide a major benefit to employers looking to fill industry 4.0 robotics and CNC technical positions,” says Paul Aiello, executive director of education at FANUC America.

“The manufacturing industry in the U.S. is facing a growing shortage of higher-skilled technicians vitally needed at the operator level. We look forward to incorporating the highly regarded MSSC foundational CPT certification programs into our robotics and CNC operator training pathways and will encourage our customers to use the CPT certifications as part of their employee training.”

Both FANUC and MSSC certify individuals through the platform NOCTI/Nocti Business Solutions (NBS). The NBS is a globally recognized platform that provides certifications assessments that qualify workers domestically as well as internationally, as seen in the ISO 17024.

FANUC and MSSC train their members on the material needed to be certified, but it is the assessments provided by NOCTI/Nocti Business Solutions that determine the individual’s eligibility for certification. The coordination between NOCTI/Nocti Business Solutions and the two organizations act as a streamline for schools and business partners when certifying individuals and workers.

FANUC’s goal is to further increase its output of fully qualified students and workers as certified robot operators, automation operators, as well as engineers and more. Students under FUNAC and its industry 4.0 Connected Smart Manufacturing will develop the necessary skills and earn the certifications, such as the FANUC Certified Robot-Operator (FCR-O1 & FCR-O2).

To expand their network and better provide U.S. workers, MSSC has just recently upgraded its Certified Production Technician (CPT) program for entry-level front-line production technicians. This program and the certification itself already prepare the workers to use many different emerging and recent technologies such as artificial intelligence (AI), 5G, industrial internet of things (IIOT), data analytics, autonomous robots, augmented reality, nano-manufacturing, and advanced materials.

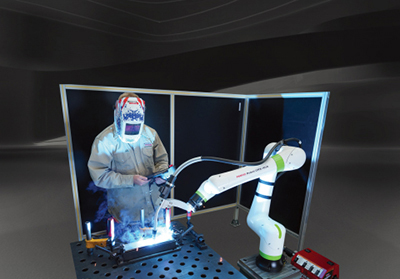

Another way FANUC has attempted to combat the lack of skilled labor in the market are through its new machines. FANUC’s new robots can handle many more tasks autonomously and with much less attention from an operator. Some of these new robots are the CRX cobot and upgraded SCARA robots.

To learn more about FANUC and its Automation demonstration, visit www.fanucamerica.com.